Shakespeare’s Globe Shop offers both print to order textiles as part of our online offering only, and a range of graphic t-shirts, sweatshirts, tea towels, tote bags and more, available both in store and online. Our textiles are printed in Wrexham, Wales by Paul Bristow Associates Ltd. a family run business with over 25 years’ experience as a textile printer and manufacturer. This bespoke textile company not only prints fabric lengths and garments in house, but also sews many of the products that they print in their workshop in Wales.

We have been working with Paul Bristow for two decades and we are excited to continue to offer high-quality textile products to our customers. By offering both digitally products on demand and screen-printed products in our onsite shop, we can experiment with more designs than ever, giving you, more choice than ever!

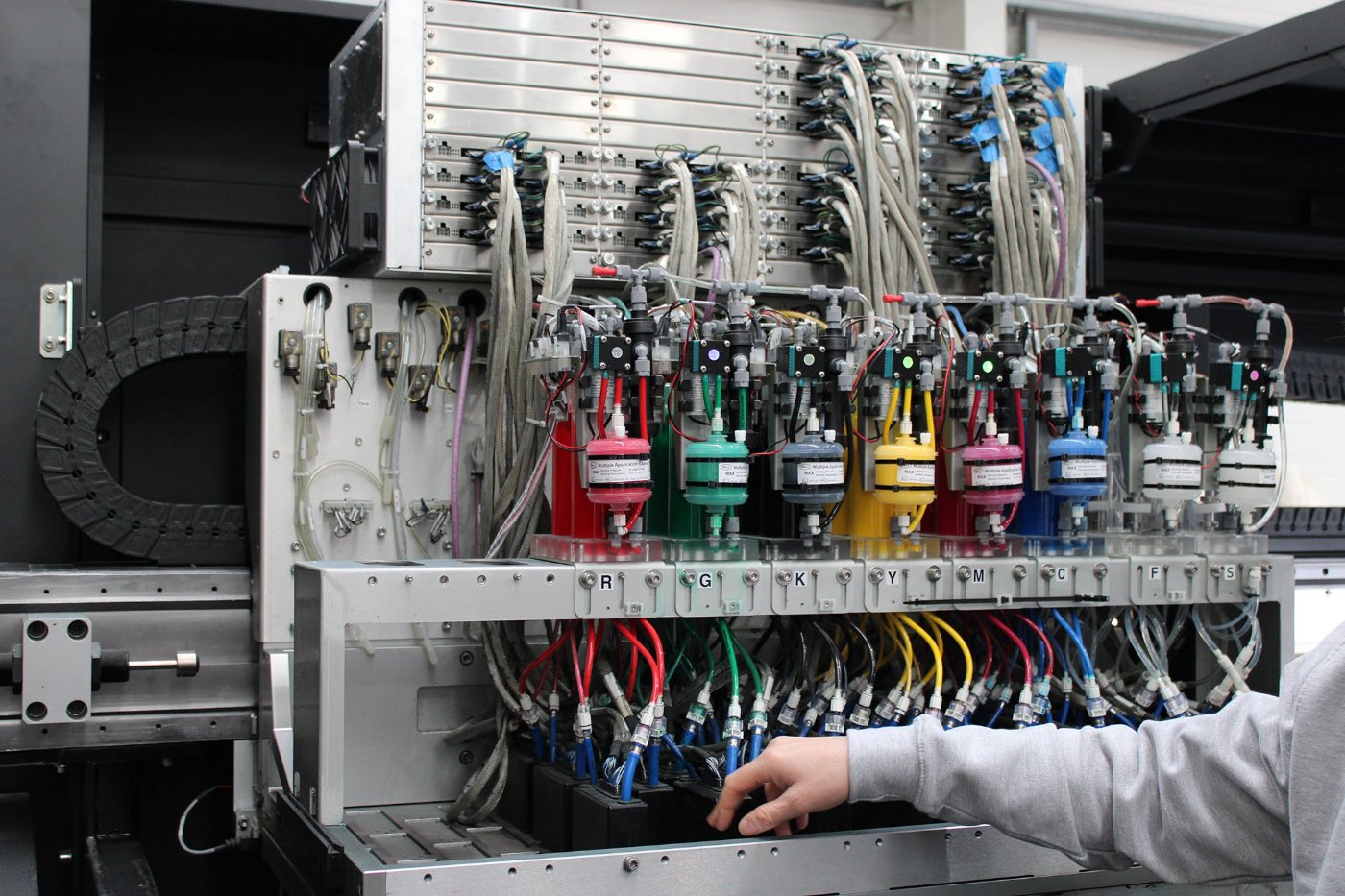

Water-based Inks

Our textiles are printed using Global Organic Textile Standard water-based inks. This is currently the most environmentally sustainable way to print textiles. These inks mean that the textiles do not require any additional processing, no steaming, and no washing. This cuts down on water waste and lessens energy consumption, as water is not needing to be turned into steam.

View of the digital printer, open, showing the intricate set up of tubes and pots of ink that transform plain white fabric into bold printed designs.

Digital Printing

Many of our textiles are printed using a digital printing method. Paul Bristow uses a digital print machine which employs 48 print heads to place ink on fabric seamlessly. Fabric is fed through the machine on a sticky belt that ensures that the fabric is properly taut. Once printed, the fabric is fed onwards to cure in a matter of minutes, moving seamlessly through a heated chamber and then carried over the few feet to the digital cutter.

This vacuum pressurised machine needs ink to be constantly circulating and at the correct temperature so that it can print correctly. If ink is not kept circulating and to temperature, then the ink may run or the print heads may block and ruin the print. The 48 print heads working simultaneously on this machine mean that there are no printing area limitations when digitally printing, giving us more creative freedom to create bigger and bolder prints.

Our Colours of Shakespeare's Globe Tea Towel being printed in Wrexham, Wales.

Digital/Robotic Cutting

Tea towels, tote bags, aprons, pencil cases and purses which have been digitally printed are cut using a digital cutter employing CAD technology to ensure as minimal fabric was as possible. Once fabric is digitally printed, it is cured and then rolled before it is transferred to the cutting table. Once cut, a technician folds and prepares the cut pieces for transfer to another workshop area to be sewn. These fabric pieces are transported between buildings by hand to ensure a smooth process throughout.

Screen Printing

Using a 12-arm machine which is manually loaded, sweatshirts and t-shirts to be screen printed whizz around the factory before being printed and then manually removed and placed on a conveyer belt that moves through another machine to be cured. Once the ink is dry the garments are removed from the machine and boxed and packed by hand before being shipped to London and stored in our warehouse underneath the Globe where shop stock is processed by our Retail Stock Controller.

Our Retail Stock Controller tried his hand at feeding sweatshirts onto the machine for screen printing and placing them on the conveyer belt to begin curing.

Sewn in Wales

A team of 14 skilled sewers produce tea towels, tote bags, aprons, pencil cases, purses, and makeup bags which we sell at Shakespeare’s Globe Shop. This team of skilled women can produce upwards of 2000 products a day when there is demand. The room is divided up into groups of sewers who perform tasks from overlocking to straight stitching, to bartacking to top stitching, ensuring that the best quality products are produced. To ensure efficiency, Paul Bristow even employ a person whose sole job is to turn the bags right side out once they are sewn. Not an easy task, but one that requires steadfast patience and attention to detail.

Bags being turned in studio in Wrexham.

All the items sewn in Wrexham are created using pieces from patterns produced in house, meaning that new a bespoke sewn items can be created throughout the year. This flexibility has been integral to Shakespeare’s Globe Shop and our ever-expanding product offering.

Print to Order Printing

Print to order clothing and textiles are manufactured in a separate building on site and produced only after an individual order or orders have been placed on our website. Orders are fed through to Paul Bristow to be fulfilled direct to the customer. These items are digitally printed after being prepared and then once cured, removed, by a machine technician. Once fully dry they are ready to be packed and sent out across the world.

Romeo & Juliet, Plague on Both Your Houses and Macbeth Quotes t-shirts curing after being screen printed.

Designed at Shakespeare’s Globe

Our graphic textiles feature exclusive designs, created in London. All our designs are inspired by Shakespeare’s words, Shakespeare’s works and the Globe Theatre. We are always adding new designs to our collection, and because of our print to order offering we can continue to expand our graphic collection without worrying about the physical space limitations that we have.

We listen to what you tell us with your purchases, when a print to order product proves extremely popular online, we bring it in store so that all our visitors can have a chance to enjoy it.

We are working on expanding our exclusive offering to ensure that all of Shakespeare’s many works have products associated with them. Keep checking back with us to see what new and exclusive graphics we’re adding throughout the year!

Written by Jennifer (eCommerce Manager)